Technical Specifications

Download specsheet

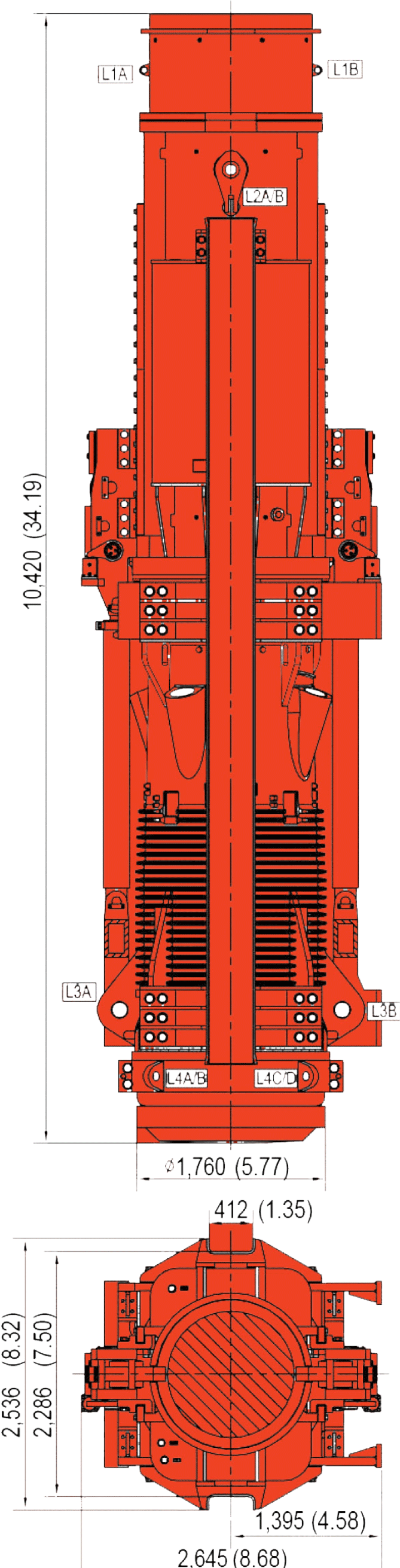

TECHNICAL PARAMETERS

| Maximum energy per blow | 3136 KNm |

| Minimum energy per blow | 2038 KNm |

| Number of blows | 33-41 per min |

| Suitable for pile diameters | 3500-6000 mm |

| Weight of the piston | 80 Ts |

| Free piston drop | 0 – 1400 KNm |

| Weight of diesel hammer | 170 Ts |

| Consumption Diesel | 215 liter per hour |

Total weight of complete operational package 425 TS

The diesel hammer D800-12 is controlled via a hydraulic power pack which is installed in a 20 ft offshore container.

The hydraulics are required for:

- to lift the piston into starting position

- to control the fuel setting

The hammer is built-in the leader. Were it can move up and down. The underside of the hammer rests upon the helmet. The leader is connected to the sleeve via the spider frame.

ADVANTAGES OF DIESEL HAMMER COMPARED TO HYDRAULIC HAMMERS

- Attractive day rate for rental (prices on request).

- Proven and reliable diesel technology.

- Less noise conductive by the sea water what results in less disturbance of the habitat of sea life. Thus less noise mitigation measures have to be taken.

- Only small and easy to handle hydraulic hoses are required for starting the diesel hammer and adjusting the fuel pumps.

- The complete configuration hammer-leader-helmet-sleeve can be loaded and stowed in an upright configuration on deck.

- Less deck space is required than a hydraulic hammer, smaller power pack.

- Each blow causes pre-tension in the pile prior impact. This diesel technology effect results in lower stresses during hammering. Thus less fatigue in the pile.

- Since the time of impact is longer for a diesel driven hammer. The energy is transferred more effectively into the pile.

- 75% less fuel consumption compared to hydraulic hammer with the same pile driving capacity

- Less lubrication (30% to 40%) is required cause synthetic oil is used and a 2 stroke diesel engine.